INDEPENDANT // PRODUCT DRIVEN DEVELOPMENT

workflow

product of many experts

InteSpring adapted a simple modular system for our consultancy services consisting of 4 sequential phases. Each phase increases in workload and cost, but each phase also has no obligation to proceed to the next if services are not up to expectations or the solution is no longer feasible: Minimizing risk for the client.

The system is built to maximize flexibility for adaptation to any project, no matter at what stage our services are needed.

modular

FOR every project

Start from which phase is appropriate to your specific level of development.

fast

development

Get results quick with InteSprings specialized network of partners and tools.

RISK

MINIMIZED

Keep control of the development of your product through our transparent workflow.

BEFORE

BEFORE

AFTER

AFTER

THE WORKFLOW:

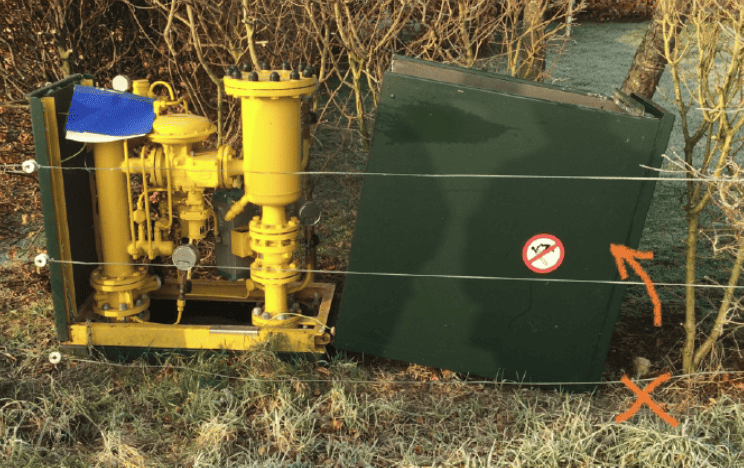

So you have a product, but it is unsafe to use around people. Or perhaps you have an idea for an exoskeleton or wearable device, but have no experience with how to put devices on people. Maybe your R&D department has developed a product only to find out the the motor needed to move a component up and down is too bulky and too slow. No matter where you are in your design process, contact InteSpring. We will offer:

FEAsibility

In the case of the Enexis enclosure, InteSpring finished a report indicating that indeed, with the addition of a simple spring system, the lid could de made virtually weightless. Within 4 weeks it was shown that the added cost of the spring would easily outweigh the benefit to employee health.

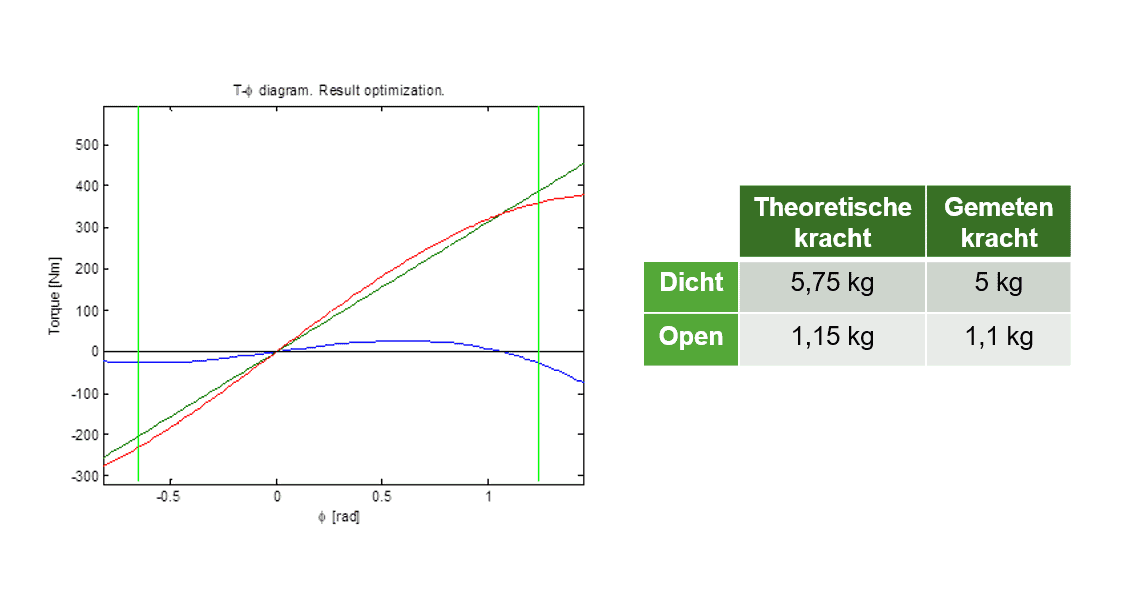

DEmonstrator

DEmonstrator

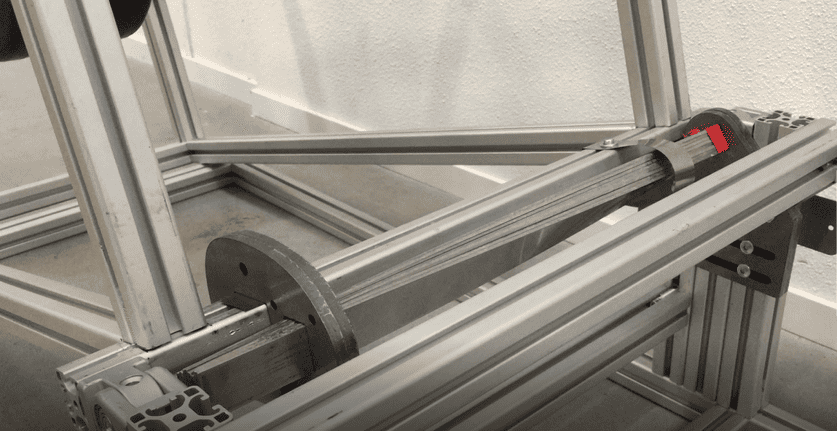

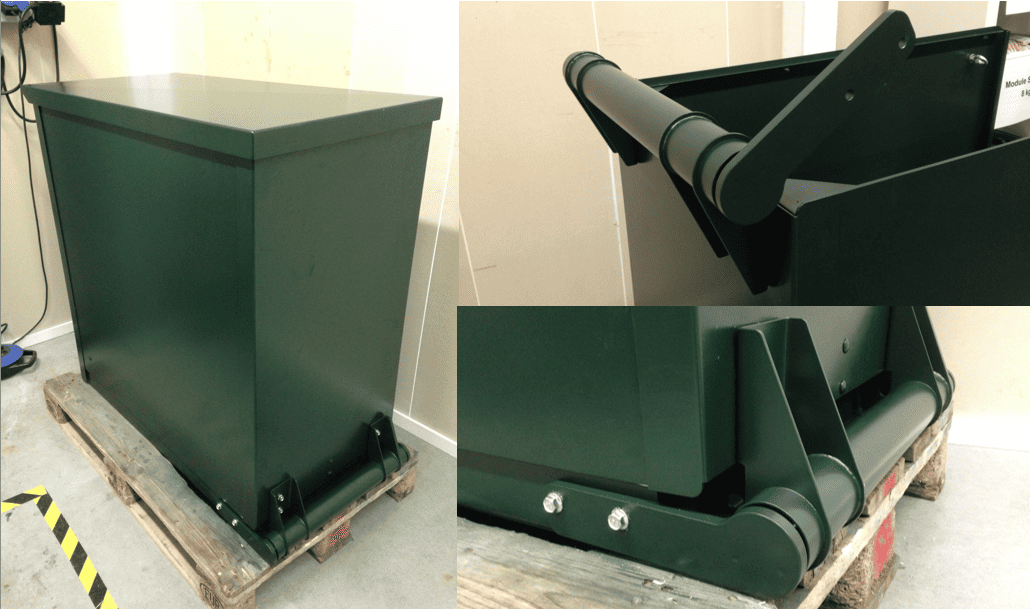

InteSpring provided machine drawings for a simple proof-of-concept prototype. Together the success parameter was set at a experienced load to the service engineer of 5kgs, a 90% reduction. In 6 weeks InteSpring had the components manufactured and assembled a physical prototype.

See the before and after video at the bottom of this page.

DEsign

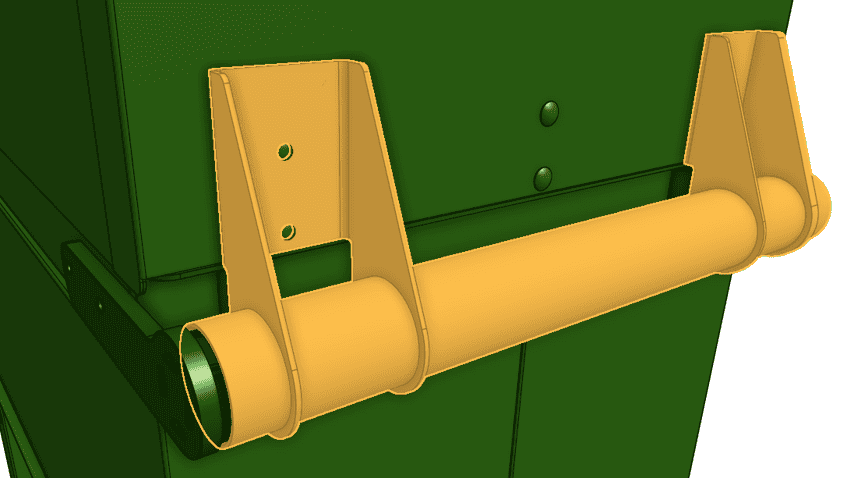

In Enexis’ case, InteSpring took over most of the development for the whole product, though with regular feedback sessions from Zadors own design team. The CAD drawings, the spring simulations, and the material analysis was completed in a 8 week period. A functional prototype was delivered.

product

Using InteSprings balanced motor torque reduction, a powered test setup was made to investigate the total solution lifecycle. With a large enough sample set it was shown that the lifecycle of the hinge mechanism far outlived the lifecycle of the enclosure itself or the gas installation within. Within 16 weeks a supply chain was setup from Zador and InteSprings combined network of preferred partners, and the first series production enclosures were produced. Due to Zadors expertise in metalwork, they took over the complete supply chain and now sell the product to Enexis under their own licence.

End

Congratulation! You have a profitable product on the market, increasing your profit while increasing safety and reducing cost to the environment. It was a pleasure doing business, please keep InteSpring in mind for future R&D endeavors.

Enexis had won this battle against the growing musculoskeletal injuries and the NIOSH-score-penalties.